Automation

and process

innovation

drives our progress

in spawn making

Production

The Technology Behind the Spawn

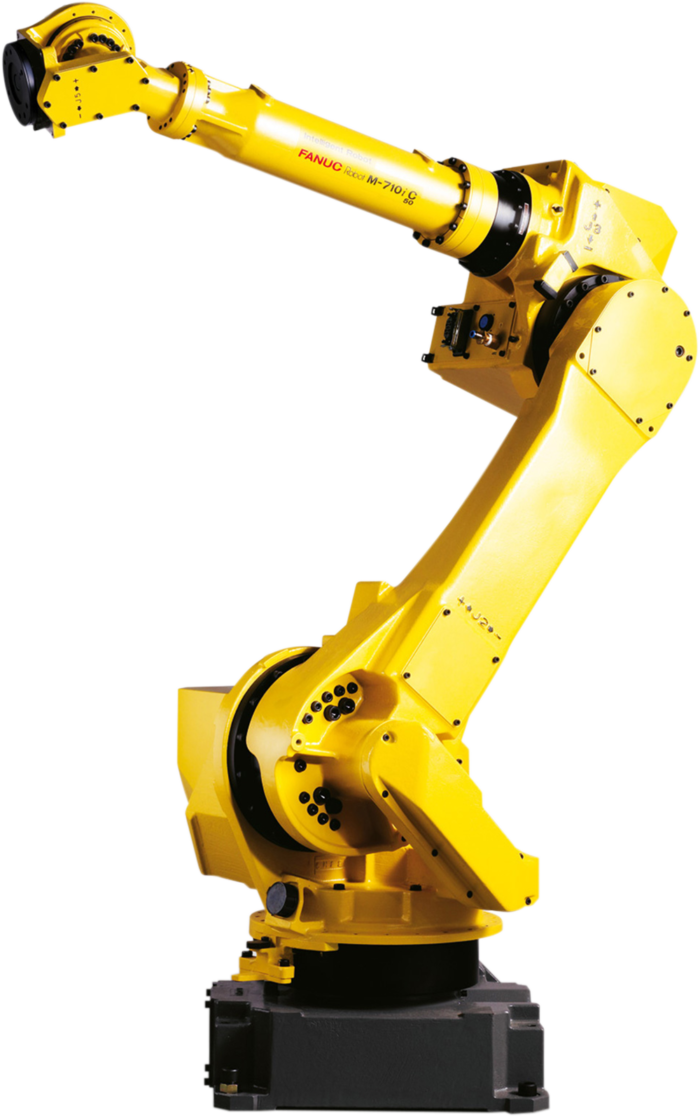

Sylvan has been dedicated to mushroom spawn innovation since its early beginnings, providing consistent, innovative spawn products to mushroom growers around the world. High levels of automation throughout the production process ensures control and consistency, creating the highest quality products for our customers.

In addition to our wide collection of strains, we offer a selection of substrates including grain and non-grain based. We also offer various packaging solutions including boxes, racks and disposable spacers to meet your logistic preferences.

Sylvan produces not only through highly automated V-blender technology but also applies flexible autoclave batch process methods, which allows us to serve customers big and small with any type of strain or spawn base they desire.

Raw material sourcing: All raw materials are carefully selected to provide the best nutrients available to the finished product.

Mixing, Cooking & Sterilization: V-shaped twin shell high capacity blenders rotate and tumble ingredients creating evenly blended, sterile substrates to be inoculated. Alternatively substrate can sterilized in autoclaves before inoculation, allowing us to offer flexibility in handling various substrates for our customers.

Inoculation and cleanroom: Pre-tested inoculum and sterilized substrate are mixed and sealed in sterile breathable bags in clean rooms. Sylvan has developed the industry’s most advanced system for inoculum production, safeguarding the integrity of all spawn produced.

HEPA filters trap particles & contaminants: Cleanroom teams are extensively trained in contamination control and follow precise handling procedures.

Solid substrate fermentation, control & cool down: Bags are moved to environmental controlled growing rooms for optimum mycelium development. After a number of weeks of controlled growth, they are transferred to cold storage rooms allowing for growth completion and product stabilization.

Inspection, packing & dispatch: Each product is inspected before customer dispatch. Product is either packed on freezer spacers, in boxes or on racks.

Interested in our spawn production process? Then contact us to book an appointment to visit our facilities, we would be delighted to show you around!